Many of our customers ask: How to Extend Service Life of SiC Heating Elements? This post will give you an answer.

Learn more about SiC Heating Elements (Silicon Carbide Rod)

Electric heating elements are a popular choice of many heat treaters. They come in a variety of shapes, sizes, and materials. One of the most common types are silicon carbide heating elements, They are used extensively throughout the heat-treating industry when high temperatures, maximum power, and heavy-duty cycles are required. Let’s learn more.

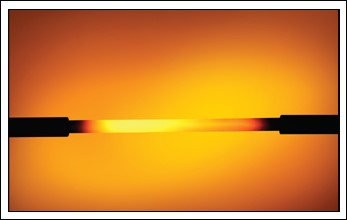

A silicon carbide (SiC) heating element is typically an extruded tubular rod or cylinder made from high-purity grains of silicon carbide that are fused together by either a reaction-bonding process or a recrystallization process at temperatures in excess of 3900°F (2150°C). The result is a chemically stable material with a low thermal expansion coefficient and little tendency to deform.

How to Extend Service Life of SiC Heating Elements

To maximize SiC heating elements life, be sure to do the following:

1. Handle the elements with care – Silicon carbide heating elements have low tensile strength and, therefore, are sensitive to mechanical damage from rough handling, dropping (even in the packaging) or forced bending that can occur during storage, unpacking or installation.

2. Match resistance – The purpose of matching resistance of elements is to improve their life and to improve temperature uniformity in the furnace.

Silicon carbide heating elements are typically factory tested with the test amperage marked on the shipping box and/or the element. Elements can be connected in parallel (preferred since they tend to come into balance in use), series or series-parallel.

Elements connected in parallel should be matched in resistance within ±20%, while elements connected in series should be matched within ±5%.

3. Choose the proper size element for the equipment – If there are any doubts about the size to use, check the design parameters with the original furnace equipment manufacturer.

4. Install carefully – Check that the terminal holes through the insulation are in alignment so that the elements slide in without striking the opposite side or are put under tension due to forcing them into position. Be sure to center the elements in the furnace chamber so that no portion of the heating section of the element is in the brickwork.

5. Pack the element with ceramic fiber to a depth of about 1 inch (25 mm) so as to avoid heat loss, but be sure that the terminal ends of horizontally mounted elements lie flat in the terminal holes and are supported by the furnace walls.

6. Use the lowest voltage that will maintain the desired furnace operating temperature. This will ensure the lowest possible surface temperature of the element and lengthen its service life.

7. Run the correct silicon carbide element watt density for the required furnace atmosphere.

8. Perform in-service inspections – Check the amperage as an indication that the elements are operating correctly.

9. Maintain matched-resistance circuits at all times. Don’t mix old and new elements in the same circuit.

10. Be sure that the elements are loose in the terminal holes not only when the furnace is cold but also hot.

Learn More details about our SiC heating elements.

04/27/2020

Follow us on Facebook