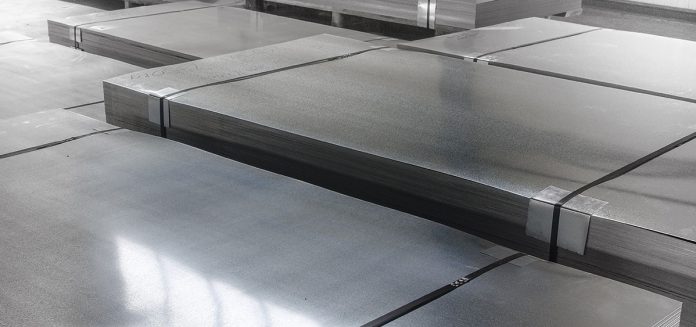

Pure Molybdenum Plate,Molybdenum Sheet

Molybdenum Plate and Molybdenum Sheet is made up of commercially pure molybdenum content. The material comprises more than 99.95% molybdenum. Molybdenum plates and sheets are the most common material chosen out of all the various molybdenum products. Many high temperature and electronic industries require molybdenum flat materials to produce furnace boats, hot zones, heat shielding, target materials etc.

Molybdenum Properties

|

Molybdenum Physical Properties |

Molybdenum Mechanical Properties |

||

| Density | 0.369 lb/in3 10.3 gm/cm3 |

Tensile Strength | 150 (1035) ksi (Mpa)-RT |

| Melting Point | 4760 °F 2625 °C |

75 (515) ksi (Mpa)-500°C | |

| Thermal Conductivity | 0.35 cal/cm2/cm°C/sec | 25 (175) ksi (Mpa)-1000°C | |

| Specific Heat | 0.061 cal/gm/°C | Elongation | |

| Thermal Expansion | 4.9 micro-in/°C x 10-6 2.7 micro-in/°F x 10-6 |

Hardness | 230 dph |

| Electrical Resistivity | 5.17 microohm-cm | Modules of Elasticity | 45000 ksi |

| Recrystalization Temp. | 1100 °C | ||

Molybdenum Applications

- Vacuum furnace shieldings

- Furnace heating elements

- Thin Film Deposition

- Furnace support frames

- Boats for sapphire crystal furnaces and vacuum furnaces

- Molybdenum sputtering targets for the vacuum coating and evaporation coating

- Molybdenum Ion sources for ion implantation equipment

- Heat Sinks

Molybdenum Properties

- High Density: 10.3 g/cm³

- High Melting Point: 2625°C (4760 °F)

- Low Vapor Pressure

- High Tensile Strength

- Low Coefficient of Thermal Expansion

- Low Electrical Resistivity

- Good Machinability

- High Absorption Capacity

- High Elastic Modulus

We have realized that a high level of quality control of Molybdenum Plate and Molybdenum Sheet is an essential prerequisite in achieving high customer satisfaction. Therefore, we put a lot of emphasis on monitoring the quality of our products throughout both the manufacturing process and inspection stage. We can always ensure the high quality of our plates and sheets products. The quality received by our customer is guaranteed to have the required flatness, machinability, and formability.

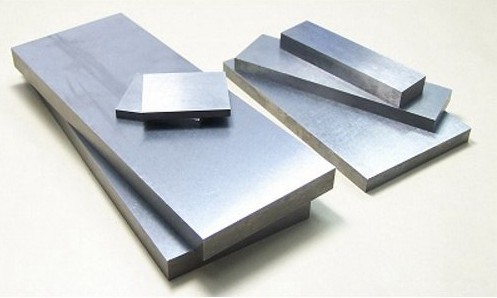

Pure Molybdeum Plate |

|

| Thickness | 0.120″ (3 mm) to 3″ (75 mm) |

| Width | Maximum 23″ (600 mm) |

| Length | Maximum 60″ (1500 mm) |

Pure Molybdeum Sheet |

|

| Thickness | 0.01″ (0.25 mm) to 0.12″ (3 mm) |

| Width | Maximum 30″ (750 mm) |

| Length | Maximum 470″ (12000 mm) |

| Surface | Ground, Chemical Cleaned, As rolled |

| Composition | Mo≥99.95% |

| Standard | ASTM B-386, Type 360, 361, 365 |

Molybdenum Plate And Sheet Standard Thickness

| Form | Size inch | Size mm | Size inch | Size mm | Size inch | Size mm | Size inch | Size mm |

| Plate/Sheet | 0.002 | 0.05 | 0.08 | 2.25 | 0.25 | 6.35 | 0.80 | 20 |

| Plate/Sheet | 0.004 | 0.10 | 0.09 | 2.30 | 0.27 | 6.86 | 1 | 25.4 |

| Plate/Sheet | 0.020 | 0.50 | 0.095 | 2.5 | 0.30 | 7.62 | 1.125 | 28.58 |

| Plate/Sheet | 0.030 | 0.75 | 0.10 | 2.54 | 0.32 | 7.95 | 1.175 | 30.15 |

| Plate/Sheet | 0.039 | 1.0 | 0.12 | 2.30 | 0.375 | 9.53 | 1.25 | 31.75 |

| Plate/Sheet | 0.050 | 1.25 | 0.125 | 3.175 | 0.395 | 10 | 1.375 | 34.93 |

| Plate/Sheet | 0.060 | 1.50 | 0.15 | 3.80 | 0.41 | 10.4 | 1.5 | 38.1 |

| Plate/Sheet | 0.068 | 1.75 | 0.16 | 4 | 0.5 | 12.7 | 1.75 | 44.45 |

| Plate/Sheet | 0.070 | 1.80 | 0.18 | 4.75 | 0.55 | 15.00 | 2 | 50.8 |

| Plate/Sheet | 0.075 | 1.90 | 0.19 | 5.0 | 0.625 | 15.88 | 2.5 | 63.5 |

| Plate/Sheet | 0.0787 | 2.0 | 0.2 | 5.08 | 0.75 | 19.05 | 3 | 76.2 |