Our Vacuum Induction Melting Furnace (VIM) employs medium frequency induction heating technology combined with an ultra-high vacuum system. This sophisticated configuration enables contamination-free melting of reactive metals and specialty alloys under precisely controlled atmospheric conditions.

Ideal for research institutions and advanced manufacturing facilities, our furnace delivers exceptional control and precision, making it the premier choice for processing a diverse range of high-value materials.

Furnace Features

- Adopt IGBT or KGPS medium frequency power supply.

- The vacuum system consists of a mechanical pump, roots pump, and diffusion pump, achieving a maximum vacuum level of 7×10-3 Pa.

- The alloy feeder is built inside. The material can be fed into the melting crucible by operating the feeder handle.

- The furnace cover features an observation window for easy monitoring of furnace performance.

- The induction heater features a rectangular copper tube secured to the electrode with mating nuts, allowing for easy disassembly.

- The crucible could be placed inside the inductor. The crucible material should follow the melt alloy type.

- Secondary direct feeding support.

Superior Material Processing Capabilities

Specifically engineered for critical applications requiring ultra-pure metallurgical results:

- Nickel-based superalloys

- High-performance steels (Tool, Maraging, Stainless)

- Reactive metals (Titanium, Zirconium, Tungsten)

- Rare-earth magnetic materials (NdFeB, SmCo)

- High-purity semiconductor materials

- Advanced intermetallic compounds

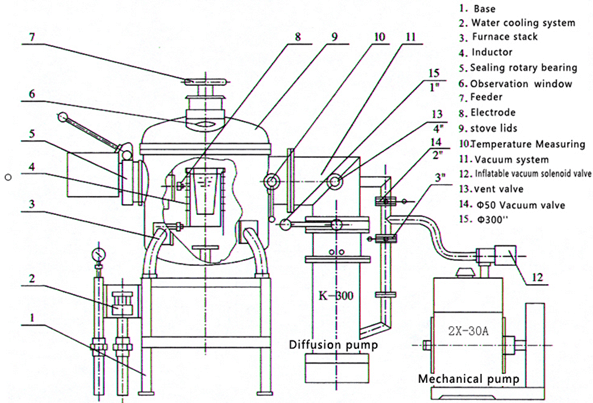

Furnace Structure & Components

- Induction Coil: The crucible is heated by electric current flowing through copper induction coils. These coils generate a magnetic field, inducing eddy currents in the metal charge within the crucible, causing heating and melting.

- Crucible: The crucible is inside the induction coil and holds the metal to melt. Crucibles are typically made of refractory materials to withstand the high temperatures of the molten metal. For example: Magnesia crucible, alumina crucible, zirconia crucible, graphite crucible, etc.

- Vacuum Chamber: The vacuum chamber encloses the crucible and induction coil, creating a sealed environment. Air is evacuated from the vacuum chamber by a vacuum system to prevent oxidation and contamination of the metal during the melting process.

- Vacuum System: Vacuum pump, vacuum gauge, vacuum valve, etc. Used to evacuate air from the vacuum chamber and maintain the required vacuum level. Normally, Max. vacuum 7×10-3 Pa is enough.

- Furnace Body: The furnace body and lid have water-cooled interlayers to ensure that the surface temperature of the furnace body does not become excessively high.

- Furnace Tilting Mechanism: Used to tilt the furnace body to pour the molten metal into a mold.

- Medium Frequency Power Supply: IGBT or KGPS medium frequency power supply. Provides medium frequency alternating current to the induction coil.

- Electrical Control System: Used to control various parameters during the melting process, such as power, temperature, and time.

Vacuum Induction Melting Furnace showcase

Technical Specifications for 20kgs |

|||||

| Crucible effective volume | 4L (Other size can be customized) | ||||

| Crucible effective capacity (Steel) | 25kgs (Other size can be customized) | ||||

| Max temperature | 2000 ℃ (Requires Crucible support) | ||||

| Max melting vacuum | ● 7×10-3Pa ● Vacuum time: open the diffusion pump when preheating is complete, then up to 7×10-3Pa in 30 minutes. |

||||

| Rated power | 120KW | ||||

| Rated voltage | 375V | ||||

| Power frequency | 50HZ | ||||

| Rated frequency | 1500~2500HZ | ||||

| Heat element | Induction copper coil | ||||

| Vacuum system | ● 70L/s Double-stage Rotary vane mechanical pump ● Dia.300mm diffusion pump, Max. pumping speed: 5000L/s ● Dia.300mm diffusion pump clod trap, effective cooling cycle for pump oil ● Dia.300mm diffusion pump flapper valve + Dia.80mm former pump flapper valve ● Stainless pipe + stainless bellows |

||||

Furnace Schematic |

|||||

|

|||||

2 vacuum induction melting furnaces were delivered to our European customer.

Standard Size:

| Model | Capacity (kgs) |

Frequency (HZ) |

Power (KW) |

Max.Vacuum (Pa) |

Cooling water consumption (T/H) |

| BR-RLL-10 | 10 | 3000 | 60 | 7×10-3 | 10 |

| BR-RLL-25 | 25 | 2500 | 120 | 7×10-3 | 15 |

| BR-RLL-50 | 50 | 2000 | 160 | 7×10-3 | 25 |

| BR-RLL-100 | 100 | 2000 | 200 | 7×10-3 | 30 |

| BR-RLL-200 | 200 | 1000 | 200 | 7×10-3 | 35 |

| BR-RLL-300 | 300 | 800 | 250 | 7×10-3 | 40 |

| BR-RLL-500 | 500 | 800 | 350 | 7×10-3 | 50 |

| BR-RLL-1000 | 1000 | 800 | 400 | 7×10-3 | 70 |

*Other sizes can be customized

Vacuum Induction Melting Furnace for Lab:

|

Model |

Temperature |

Power |

Max. vacuum |

Capacity |

| BR-KZG-3 | 0-1750℃ | 35kW | 5*10-3pa | 5kg |

| BR-KZG-5 | 0-1750℃ | 45kW | 5*10-3pa | 5kg |

| BR-KZG-10 | 0-1750℃ | 65kW | 6.7*10-3pa | 10kg |

| BR-KZG-25 | 0-1750℃ | 100kW | 6.7*10-3pa | 25kg |

| BR-KZG-50 | 0-1750℃ | 160kW | 6.7*10-3pa | 50kg |

| BR-KZG-100 | 0-1750℃ | 200kW | 6.7*10-3pa | 100kg |

Case:

Vacuum Induction Melting Furnace Successfully Installed in Turkey

More Vacuum Furnace:

- Vacuum Brazing Furnace

- Vacuum Furnace

- Vacuum Furnace up to 2200℃

- Vacuum Gas Quenching Furnace

- Vacuum Hot Press Furnace

Follow us on Facebook