High Temperature Vacuum Brazing Furnace, Molybdenum Chamber up to 1500℃

Brother high-temperature Vacuum Brazing Furnace can reach 1500℃, suitable for stainless steel, CBN tools, and Diamond tools brazing in the vacuum environment. Due to its high vacuum and high temperature, it can also be used for sintering and heat treatment of other workpieces.

- Stainless steel brazing

- CBN tools brazing

- PCD tools brazing

- Diamond tools brazing

- Copper / sliver / nickel / aluminium base brazing

Advantages of our brazing furnace:

- No surface oxidation or discoloration

- Minimal distortion

- Repeatable good brazing quality

- Clean, safe, quiet, and efficient

Vacuum Brazing Furnace in the Lab

For Stainless Steel Brazing:

For Copper Brazing:

For Diamond Tools, PCD tools, CBN tools Brazing:

Due to the slow cooling of the ordinary brazing furnace, the production efficiency is seriously affected. In order to accelerate the cooling rate, our company combined with years of production practice experience developed a vacuum brazing furnace rapid cooling system. The high-temperature nitrogen in the furnace is forcefully pumped out by the vacuum fan, cooled by the cooling water bag, and then sent back to the furnace by the vacuum fan. This rapid cycle leads to rapid cooling.

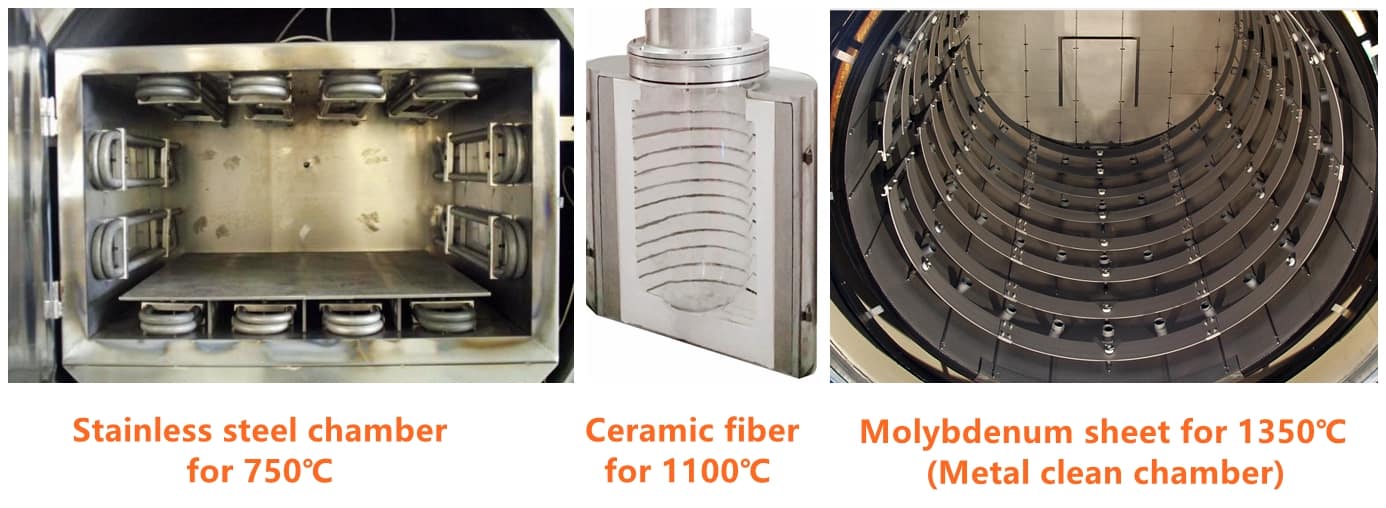

3 types of Furnace Chamber for optional

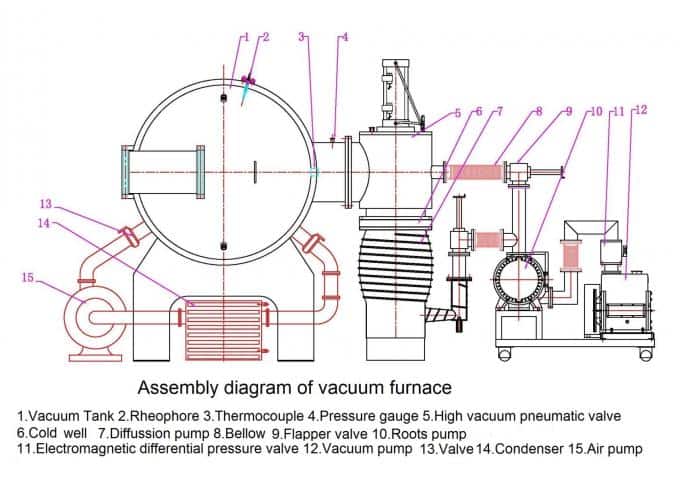

Vacuum System:

Technical Specifications of Vacuum Brazing Furnace:

Technical Specifications |

|

| Working Temp. | 750℃ (Alloy tube heaters) |

| 1100℃ (Heating wires) | |

| 1350℃ (Molybdenum strap heaters ) | |

| 1500℃ (Customizable) | |

| Furnace chamber | 750℃ (Stainless steel sheets) |

| 1100℃ (Ceramic fiberboard) | |

| 1350℃ (Molybdenum sheets and Stainless steel sheets ) | |

| 1500℃ (Customizable) | |

| Furnace Structure | Double layers Carbon steel casing with water cooling system to ensure the surface is below 30℃ |

| The furnace door inside is polished stainless steel | |

| Working Voltage | 380V 50HZ 3P (or according to your standard) |

| Max. Power | 3KW–180KW |

| Temperature control system | |

| Temperature Control | 50 segments programmable and PID auto control or PLC |

| Upper limited alarm and deviation alarm | |

| Temperature Accuracy | +/- 1℃ |

| Heating Rate | < 20℃/min |

| Temperature Alarm | Over-temperature alarm |

| Broken thermal-couple alarm | |

| Thermocouple | K / S type |

| Touch Screen | 10 inches LED touch screen |

| Over 30 working programs can be set | |

| Heating curves can be saved | |

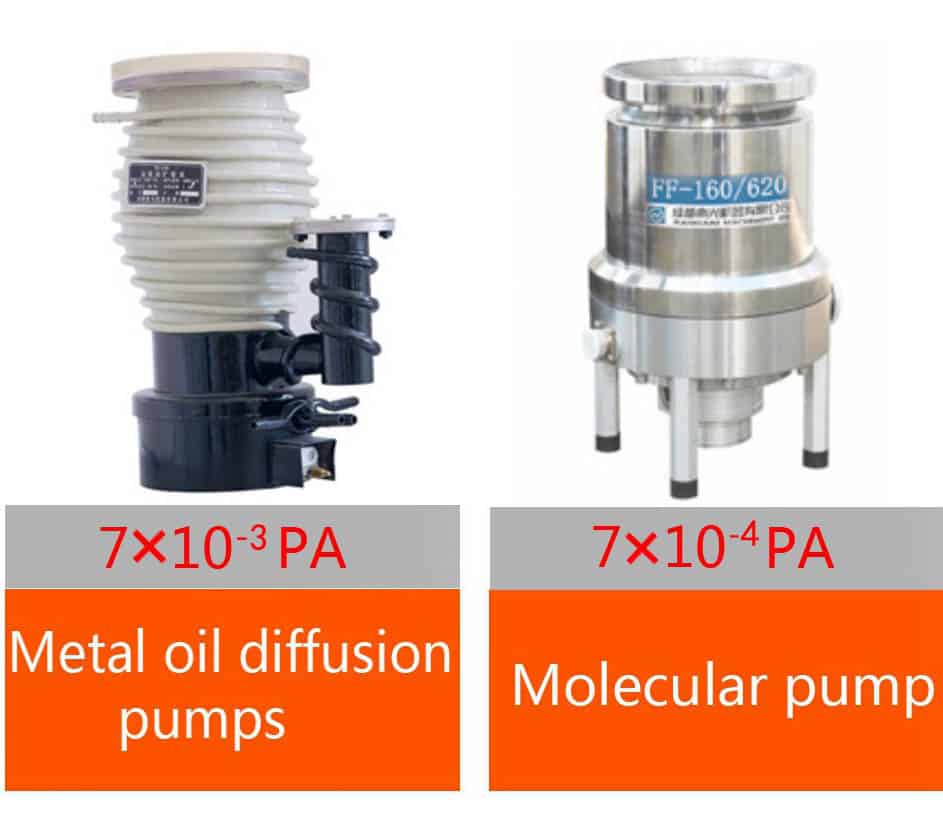

| Vacuum system | |

| Maximum Vacuum | 7×10-4Pa |

| Working Vacuum | 7×10-3Pa with Mechanical pump and Diffusion pump |

Standard Size: (other sizes can be customized)

stainless steel chamber up to 750℃

| Model | Chamber size | Max Temp. | Power | Voltage | Max. vacuum |

| BR-QHS-223 | 200*200*300mm | 750℃ | 12kW | 380V | 7×10-3 Pa

(7×10-5 mbar) |

| BR-QHS-334 | 300*300*400mm | 750℃ | 21kW | 380V | |

| BR-QHS-446 | 400*400*600mm | 750℃ | 34kW | 380V | |

| BR-QHS-557 | 500*500*700mm | 750℃ | 46kW | 380V | |

| BR-QHS-669 | 600*600*900mm | 750℃ | 64kW | 380V |

Ceramic fiber chamber up to 1200℃

| Model | Chamber size | Max Temp. | Power | Voltage | Max. vacuum |

| BR-200BF | Dia200*400mm | 1200℃ | 8 | 380V | 7×10-3 Pa

(7×10-5 mbar) |

Molybdenum chamber up to 1500℃

| Model | Chamber size | Max Temp. | Power | Voltage | Max. vacuum |

| BR-QHM-223 | 200*200*300mm | 1350℃ | 34kW | 380V | 7×10-3 Pa

(7×10-5 mbar) |

| BR-QHM-334 | 300*300*400mm | 1350℃ | 60kW | 380V | |

| BR-QHM-446 | 400*400*600mm | 1350℃ | 98kW | 380V | |

| BR-QHM-557 | 500*500*700mm | 1350℃ | 132kW | 380V | |

| BR-QHM-669 | 600*600*900mm | 1350℃ | 180kW | 380V |

If you need Max. Temp. 1500℃ Vacuum Brazing Furnace, please contact us for more details.

Vacuum Brazing Tips:

Vacuum Brazing: How to Get High-quality Brazed Joints

More Vacuum Furnace:

Follow us on Facebook