High Purity Mosi2 Heating Elements, 1700 °C / 1800 °C Moly Disilicide Heating Elements Rod

Application: Widely used in research and production of glass, ceramic, refractory, metallurgy, steel-making, crystal, electronic parts, semiconductor material. The MoSi2 Heating Elements model including BR1700 (working temperature 1600℃) and BR1800 (working temperature 1700℃)

MoSi2 Heating Elements Features:

- The Mosi2 heater has the function of antioxidant and auto repair, and suitable for different kinds of continuous working during the oxygen atmosphere.

- Molding by heat process and model size is standard, so we can produce special shapes and sizes according to customer requirements.

- Adopt a special process for joint molding with fasten welding and strong impact resistance.

- High density and excellent electrical conductivity, high heating rate, and low power consumption.

- The old one and the new one could be used together.

MoSi2 Heating Elements Properties

1.Physical properties

| Density | Bending strength |

Hardness | Porosity | Water absorption |

Thermal elongation |

Fracture toughness |

Compression strength |

| 5.8g/cm3 | 350MPa | 12.0GPa | +/-5% | 0.6 | 4% | 4.5MPa.m1/2 | 650MPa |

2.Chemical properties:

High temperature antioxidant property:

At a high temperature oxidizing atmosphere, a dense quartz SiO2 protect layer will be generated in the surface of the hot zone to prevent the element from further oxidation. When the temperature is higher than 1700C, the protection layer would be melt. Due to the effect of surface tension, quartz agglomerating into drops, and loses the protection. Then continue to use in the oxidizing atmosphere, the quartz protection layer again generate.

Note: the element can’t be used for a long time in the temperature range of 400C to 700C, otherwise it will be strongly oxidated and damaged

3.The influence of the different atmosphere

| Atmosphere | Max element temperature | |

| 1700 type | 1800 type | |

| Air | 1700C | 1800C |

| He Ar Ne | 1650C | 1750C |

| SO2 | 1600C | 1700C |

| CO N2 | 1500C | 1600C |

| (Wet) H2 | 1400C | 1500C |

| (Dry) H2 | 1350C | 1450C |

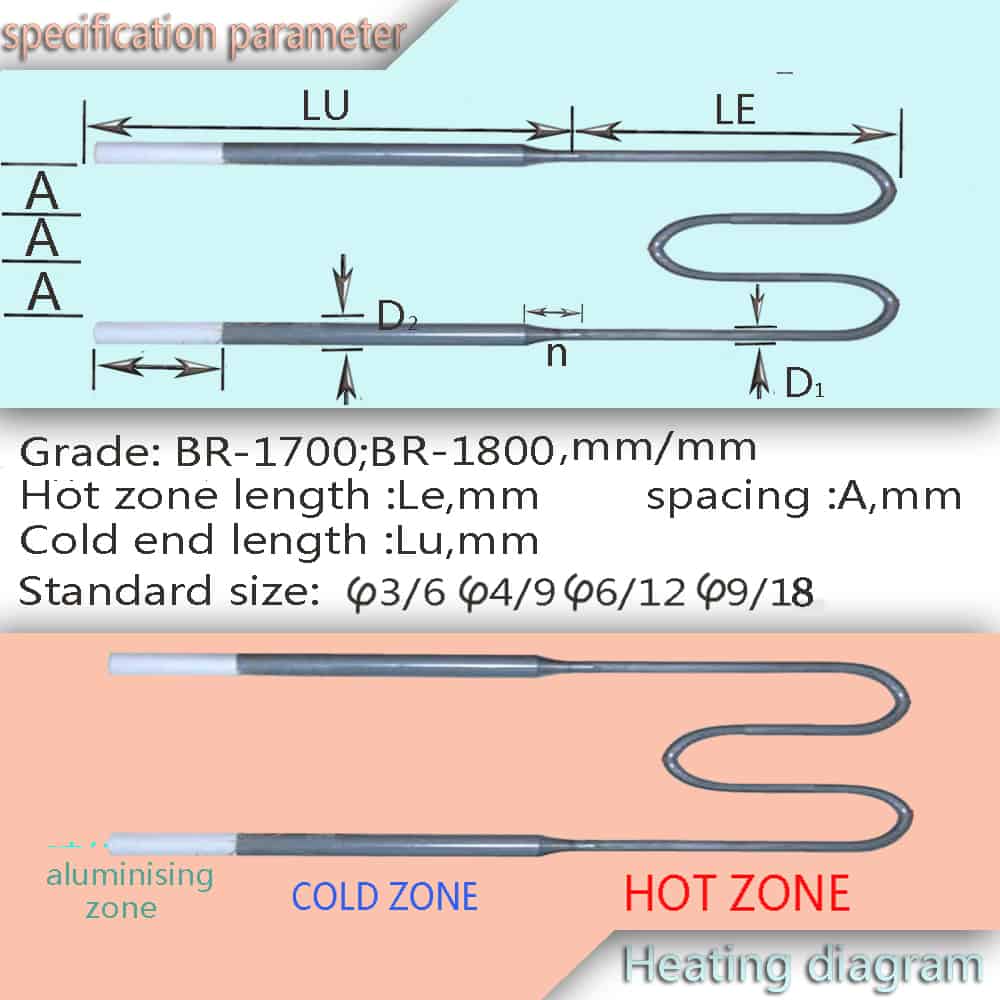

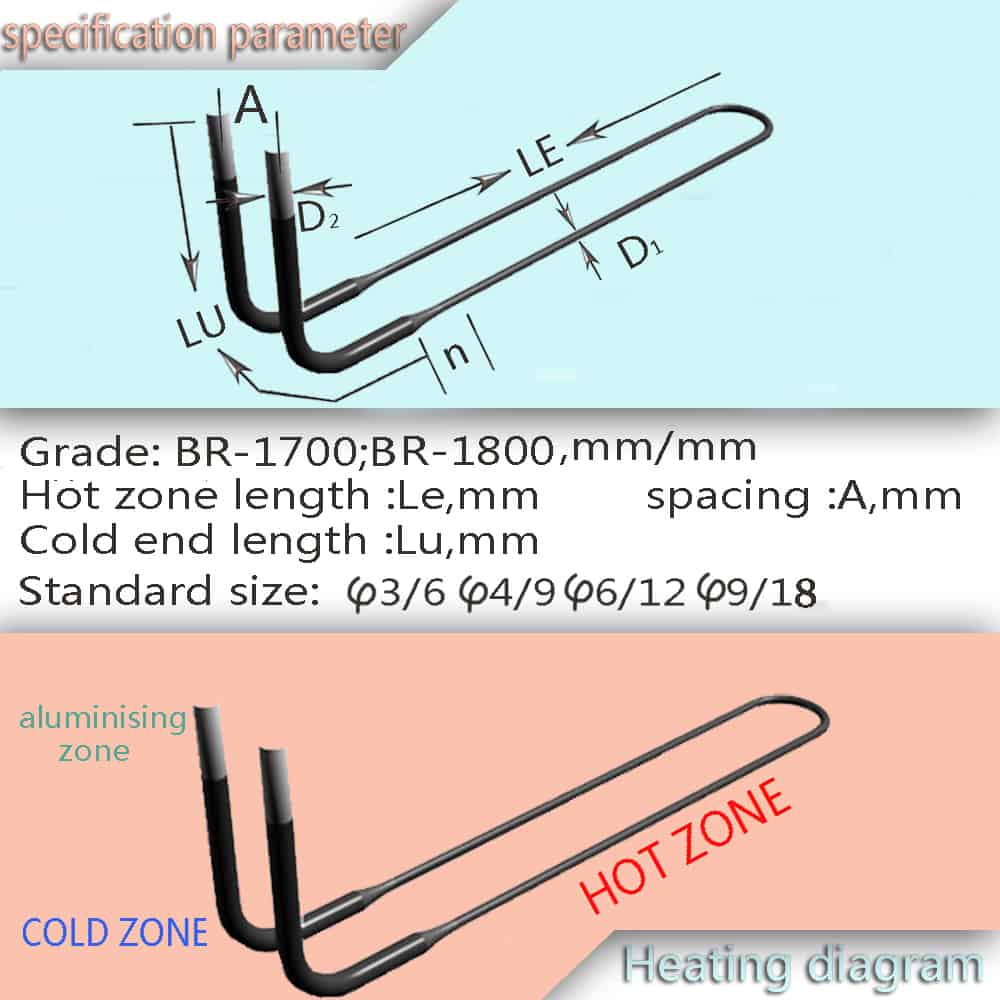

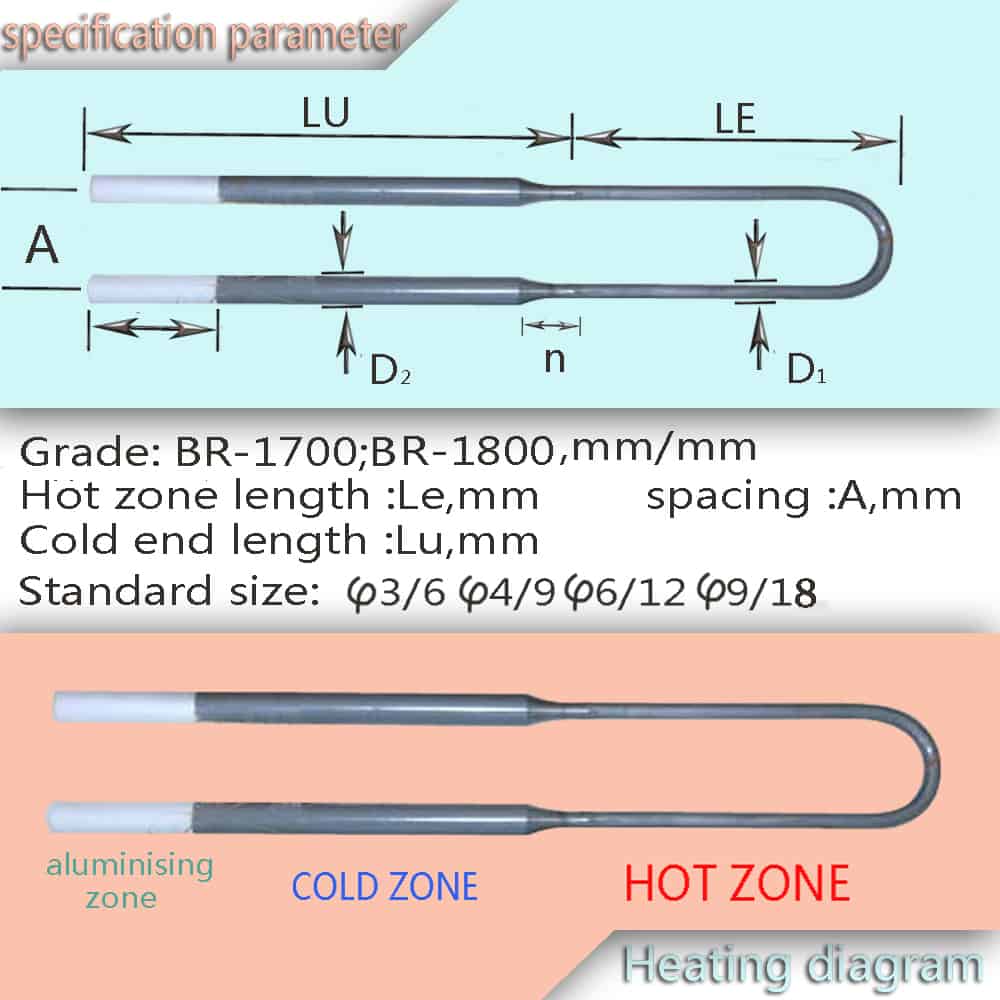

| Heating zone dia.

D1 |

Cooling zone dia.

D2 |

Heating zone length

Le |

Cooling zone length

Lu |

Central distance

A |

| 3mm | 6mm | 80-300mm | 80-500mm | 25mm |

| 4mm | 9mm | 80-350mm | 80-500mm | 25mm |

| 6mm | 12mm | 80-800mm | 80-1000mm | 25-60mm |

| 7mm | 12mm | 80-800mm | 80-1000mm | 25-60mm |

| 9mm | 18mm | 100-1200mm | 100-2500mm | 40-80mm |

| 12mm | 24mm | 100-1500mm | 100-1500mm | 40-100mm |

| Note: 1.Special size is customizable.

2.Delivery time only need 3 days for normal size |

||||

| Model: BR1700 (working temperature 1600℃) and BR1800(working temperature 1700℃) | ||||

Please confirm the following data before order our MoSi2 Heating Elements:

1. Type (U, W, L)

2. Diameter: D1, D2

3. Heating zone length: Le

4. Cooling zone length: Lu

5. The distance between two terminals: A

Recommendation:

How to Extend MoSi2 Heating Elements Life

How to Replace MoSi2 Heating Elements (Silicon Molybdenum Rods)

Follow us on Facebook