There is a wide range of vacuum equipment, but they all have a pumping system to remove the air or gas to obtain the required vacuum conditions inside the vacuum chamber.

What is a complete vacuum system?

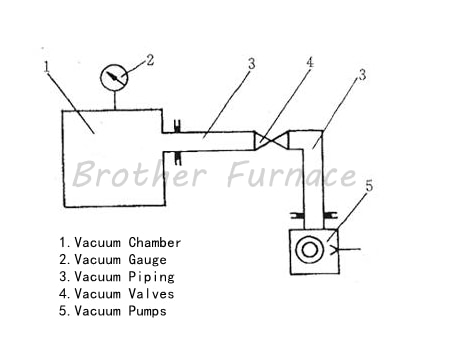

A vacuum chamber, which is connected to a vacuum pump by pipes and valves, plus a vacuum measuring device, constitutes the simplest vacuum system. (as in Figure 1).

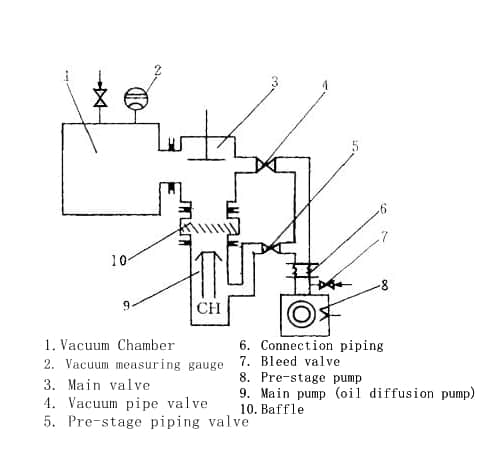

When a high vacuum is required, a high vacuum pump needs to be added to the vacuum system. In addition, valves also need to be added to the inlet and outlet of the high vacuum pump so that the high vacuum pump can maintain the vacuum separately.

If the high vacuum pump is an oil diffusion pump, in order to prevent a large amount of oil vapor return into the pumped vessel, a baffle (as shown in Figure 2) is usually added at the inlet of the oil diffusion pump. According to the requirements, a dust collector, vacuum relay gauge head, vacuum flexible connection pipe, vacuum pump inlet bleed valve, etc. can also be added to the vacuum system, so as to constitute a more perfect high vacuum system.

In any vacuum system which is composed of two or more vacuum pumps in series, the low vacuum pump is usually called the Pre-stage pump (or pre-pump), and the highest vacuum pump is called the main pump of the vacuum system. The ultimate vacuum and working vacuum in the pumped vacuum chamber are determined by the main pump. The valve at the entrance of the main pump is called the main valve.

To sum up, a better vacuum system consists of the following:

- Vacuum pumping: Pre-stage pump, main pump

- Vacuum valves

- Connecting pipes

- Vacuum measuring devices

- Other components: Baffles, dust collectors, vacuum relay gauge heads, gas storage tanks, etc.

Learn more about our Vacuum Furnace

Follow us on Facebook