This lift-type ceramic debinding and sintering furnace is mainly used for debinding and sintering, wafer annealing, etc. It can also be used for high-temperature sintering and annealing of common metals or other materials. Maximum temperature 1750℃, ceramic fiber furnace chamber, touch screen control, lift type just needs a small area with large loading capacity. Bogie hearth design, easy to put and take the material. Low cost, high overall production efficiency, convenient operation, loved by domestic and overseas customers.

Applicable Materials: Si₃N₄ (nitridation of silicon powder), AlN (nitridation of aluminum powder), High-purity alumina (Al₂O₃) substrates, Silicon carbide (SiC) ceramics, Zirconia ceramics (Y-TZP), etc.

It can also be used for powder metallurgy, Metal Injection Molding (MIM), and the sintering of high-temperature alloys. Additionally, it can be employed in the preparation of cathode materials for lithium iron phosphate batteries (LiFePO₄).

Main Features of Ceramic Debinding and Sintering Furnace

Smart Temperature Control & Exhaust Management

- Integrated air preheating (up to 400°C) exhaust system with gas filters and thermocouples for accelerated catalytic debinding.

- Four-sided heating with excellent uniformity.

- Automatic airflow control for efficient emissions removal.

- Top-chimney exhaust structure enhances gas flow dynamics.

Energy-Efficient Construction

- Multi-layer refractory materials:

– Hollow-sphere alumina (acid/alkali/molten metal corrosion-resistant, lightweight).

– Interlocking hearth structure (30% thermal stress reduction, improved thermal shock resistance).

– Mullite furnace base (50% enhanced load-bearing capacity). - Ceramic fiber-lined exhaust ports (erosion-resistant, zero slagging).

Full-Process Automation

- 10-inch intelligent panel with 30 programmable process curves.

- Three-phase asynchronous motor + worm gear lifting system:

– Linear guides + self-locking mechanism (±0.5mm synchronization accuracy, anti-drop protection).

– Programmable automated lifting sequences. - Automatic loading cart with dual safety limit switches.

Air-Cooled Debinding

- The variable-frequency fan system reduces energy consumption by 25%.

- Gas convection accelerates heat transfer, shortening debinding time by 30-50%.

- Minimizes carbon residues, pores, cracks, and impurities from binder decomposition.

- Lower energy consumption with improved yield rate.

Safety Protection

- Dual protection: Over-temperature/thermocouple failure auto power cutoff.

- Thermocouple break alarm with audible/visual alerts and emergency shutdown.

Applications

- Capacitor Ceramics

- Piezoelectric Ceramics

- Ceramic Cutting Tools

- Ceramic Bearings

- Artificial Bone (Bioceramics)

- Dental Ceramics

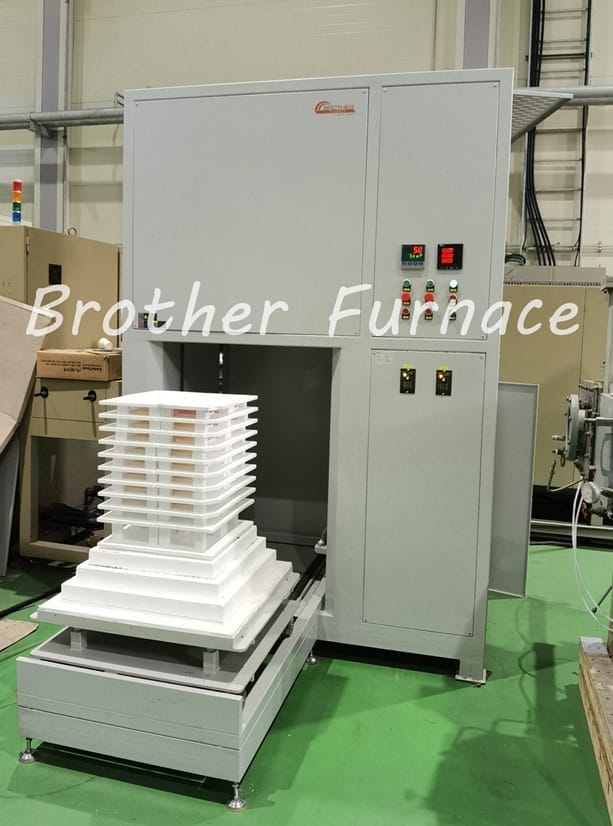

10 sets of ceramic debinding and sintering furnaces are ready.

The ceramic debinding and sintering furnace at our South Korean client’s site.

Technical Specifications |

|

| Max. temperature | 1750 ℃ (<2hour) |

| Working temperature | 800-1700 ℃ |

| Temperature controlling | ● PLC touch screen control, can record temperature curve, current curve. ● programmable for precise control of heating rate, cooling rate, and dwell time. ● Overheating & broken thermocouple broken protection. ● Over-temperature protection and alarm allow for operation without an attendant. |

| Temperature accuracy | ± 1℃ |

| Heating rate | 0-15 ℃/min |

| Thermocouple | B type with 99.7% purity Alumina tube |

| Heating element | MoSi2 heating elements |

| Furnace Chamber | Three layers of ceramic fiber insulation materials ● First layer: 1800℃ ceramic fiber board ● Second layer: 1600℃ ceramic fiber board ● Third layer: 1260℃ ceramic fiber board |

| Furnace structure | Double-layer steel casing with dual cooling fan, surface temperature below 60℃ |

| Furnace door | ● Bottom loading open ● Power cutting off when furnace door open |

| Working voltage | 110V or 220V, 50HZ/60HZ, 1 phase (As per your order) |

| Warranty | ● One year limited warranty with lifetime support. (Consumable parts such as thermocouple is not covered by the warranty, please order the replacement at related products). ● ATTENTION: Any damages caused by the use of corrosive and acidic gases are not under the coverage of One Year Limited Warranty. |

| Certifications | CE |

Ⅱ. Application Notes |

|

| Using Attentions | ● Toxic or explosive gases are not recommended for use with this furnace without necessary safety controls and supervision. ● Small cracks may appear on the surface of the refractory ceramics over extended use. This is a normal occurrence and the cracks may be repaired with alumina coating. |

Ceramic debinding and sintering furnace standard size:

| Model | Max. (℃) |

Chabmer size (WxHxD in mm) |

Liter (L) |

Power (KW) |

Phase | Heater | Thermo couple |

| BR-17BL-8 | 1750 | 200*200*200 | 8 | 5 | 1 | Mosi2 heating elements |

B type |

| BR-17BL-12 | 200*200*300 | 12 | 7 | 1 | |||

| BR-17BL-27 | 300*300*300 | 27 | 9 | 1 | |||

| BR-17BL-36 | 300*300*400 | 36 | 11 | 3 | |||

| BR-17BL-64 | 400*400*400 | 64 | 18 | 3 | |||

| BR-17BL-125 | 500*500*500 | 125 | 40 | 3 |

Note: Other sizes can be customized.

See our other Muffle furnaces:

Follow us on Facebook