CE Standard Electric Muffle Furnace 1800 ℃ Max.

BR-18HM Super high temperature muffle furnace 1800 is the CE certified muffle furnace which consists of super high-quality alumina fiber brick with ZrO2 liner and Super-1900 MoSi2 heating elements which can be used up to 1800℃. Temperature is controlled by high precision SCR (Silicon Controlled Rectifier) digital controller with accuracy +/-1℃ and 51 segments programmable. It is an ideal tool for materials annealing and sintering in your research laboratory.

Muffle Furnace 1800 type Features:

- Max working temperature 1800℃;continuous working temperature 1750℃

- Volume 1~36L

- High-quality MoSi2 heating element imported from the USA

- Ceramic fiber chamber imported from Japan, ultra-high temperature coating inside

- 51 segments programmable and PID auto control

- With over-temperature alarm function

- Double layer of furnace shell with fan cooling, the Surface temperature is less than 60℃

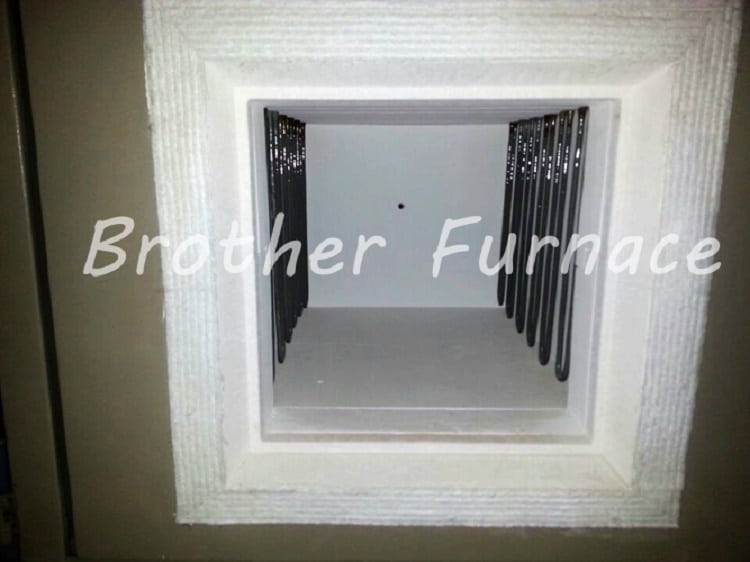

Muffle furnace 1800c mosi2 heating elements:

Ⅰ. Technical Specifications |

|

| Max. temperature | 1800℃ (<2hour) |

| Working temperature | 1750℃ |

| Standard Temperature controlling | ● PID automatic control via SCR (Silicon Controlled Rectifier) power control with phase angle

fired, current limiting resistor.

|

| Optional of Temperature controlling | ● Software (Furnace can be operated by PC by installing a control software) ● Touch screen temperature controller |

| Temperature accuracy | ±1℃ |

| Temperature Uniformity | ±5℃ over 120mm @ 1800℃ ±3℃ over 80mm @ 1700℃ |

| Heating rate | 0-15℃ /min |

| Thermocouple | B type (Pt-Rh to Pt-Rh) with 99.7% purity Alumina tube |

| Heating element | Super MoSi2 heating elements for muffle furnace 1800C |

| Muffle Furnace 1800 type Chamber | Three layers of ceramic fiber insulation materials ● First layer: 1900℃ ceramic fiber board. ● Second layer: 1700℃ ceramic fiber board. ● Third layer: 1260℃ ceramic fiber board. |

| Furnace structure | Double layer steel casing with dual cooling fan, surface temperature below 60℃ |

| Furnace door | ● Power cutting off when furnace door open |

| Warranty | ● One year limited warranty with lifetime support. (Consumable parts such as heating elements and crucibles are not covered by the warranty, please order the replacement at related products) ● ATTENTION: Any damages caused by the use of corrosive and acidic gases are not under the coverage of One Year Limited Warranty. |

| Certifications | CE |

Ⅱ. Application Notes |

|

| Using Attentions | ● The cooling rate of this muffle furnace 1800 type shall also not exceed 10℃ /min. ● Toxic or explosive gases are not recommended for use with this furnace without necessary safety controls and supervision. ● Small cracks may appear on the surface of the refractory ceramics over extended use. This is a normal occurrence and the cracks may be repaired with alumina coating. ● A refractory door block must be inserted before closing door. |

Muffle Furnace 1800C Standard Size:

| Type | Max. Temperature(℃) |

Furnace Chamber Size(mm) (Width x Height x Depth) |

Volume(L) | Rated Power(kw) |

| BR-18HM-1 | 1800 | 100x100x100 | 1 | 2 |

| BR-18HM-2 | 1800 | 120x120x130 | 2 | 4 |

| BR-18HM-3 | 1800 | 150x150x150 | 3 | 5 |

| BR-18HM-5 | 1800 | 150x150x200 | 5 | 6 |

| BR-18HM-8 | 1800 | 200x200x200 | 8 | 8 |

| BR-18HM-12 | 1800 | 200x200x300 | 12 | 10 |

| BR-18HM-27 | 1800 | 300x300x300 | 27 | 12 |

| BR-18HM-36 | 1800 | 300x300x400 | 36 | 15 |

| Note: | Special size for muffle furnace 1800C is customizable. | |||

See our other Muffle Furnace:

Tips:

- How to Extend MoSi2 Heating Elements Life

-

How to Replace MoSi2 Heating Elements (Silicon Molybdenum Rods)

Follow us on Facebook