Many customers ask how to set up a PID temperature controller for their furnaces. The following is an example of setting a PID temperature control program with a 6-segment profile, hope this can help you. If you prefer to video tutorial, please find it at the end of this article.

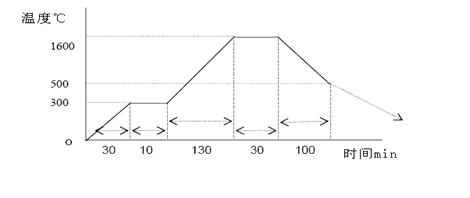

For a complicated temperature control profile, we strongly suggest you make the drawing as Fig.1 then make a form as table 1 to list all data in every segment.

Fig. 1 is the temperature profile that we would like to set.

According to this profile, you shall list all segments in the following Table

| Segment # | Symbol in Panel | Data to be In-put | Meaning in the program |

| 1 | C 01 | 0 (℃) | Initial Temperature |

| 2 | t 01 | 30 (min.) | Ramping time from 0 – 300℃

Average Heating rate is 10℃ /min |

| 3 | C 02 | 300 (℃) | Target temperature value to first

heating stage ( 300℃ ) |

| 4 | t 02 | 10 (min.) | Soaring time at 300 oC stage |

| 5 | C 03 | 300 (℃) | Temperature value at the heating flat |

| 6 | t 03 | 130 (min.) | Second Heating time from 300 -1600℃

The average heating rate is 10℃ /min |

| 7 | C 04 | 1600 (℃) | Target temperature value to peak

heating stage ( 1600℃ ) |

| 8 | t 04 | 30 (min.) | Soaring time at 1600 oC stage |

| 9 | C 05 | 1600 (℃) | Temperature value at peak heating flat |

| 10 | t 05 | 100 (min.) | Cooling time to 500℃

The cooling rate is 11℃ /min |

| 11 | C 06 | 500 (℃) | Target temperature to be cooled ( 500℃) |

| 12 | t 06 | -121 | Program end, Out-put power off. Furnace

cooling down naturally (t 06 = -121 is an order to stop running. |

Using 4 keys of to enter data listed in the above table into the controller separately, then, you finish one temperature control program finish Please be noted that “ t xx “ is the time value for the XX segment. It can be set from 1- 9999 minutes. However, if “t xx “is set as the following values, it can be as a special order. These orders only can be used in complicated multi-temperature profile programs.

If txx = 0: Controller will be paused at xx segment (Hold)

If txx = – (1-150) Negative value is a control order, which lets the program stop running, or jump to another segment.

If txx = – (Ax30+B) , here B values is 1- 30. This indicates program will jump to the segment at B value

When A=0, only execute the segment jump function.

When A=1, the program will cut off power delay

When A=4, B=1, Program will execute a “stop “order

How To Set Up a PID Temperature Controller

If you have further questions about PID temperature controller setting , please feel free to contact us.

Our Furnaces:

- Muffle Furnace 1800℃ Max.

- Muffle Furnace 1700℃ Max.

- Vacuum Tube Furnace

- Vertical Tube Furnace

- Rotary Tube Furnace

Follow us on Facebook