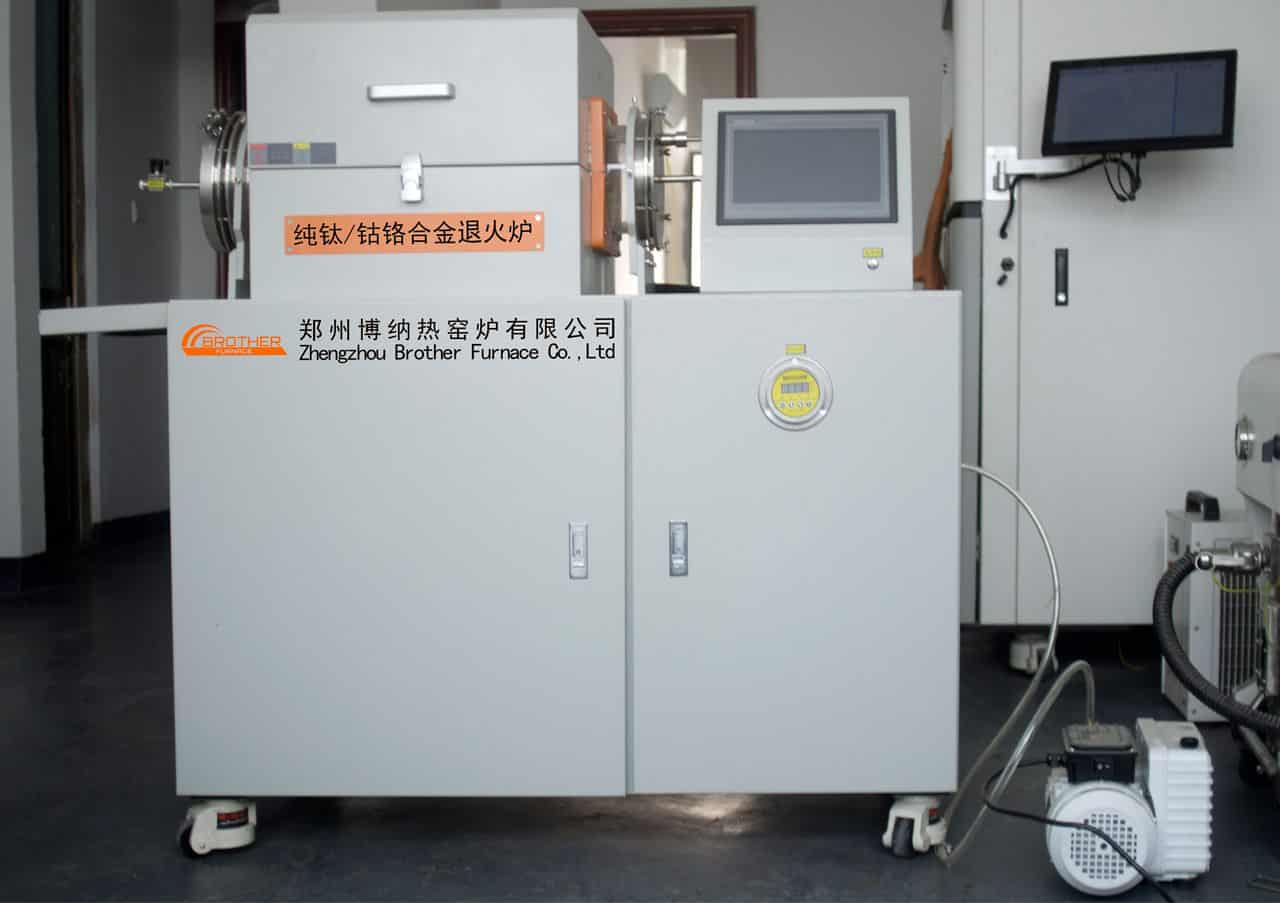

3D Printing Soft Metal Sintering Furnace for Ti and Co-Cr

This 3D Printing Soft Metal Sintering Furnace is mainly used for Titanium Alloy,Cobalt-chrome, up to 1200 degrees,with a vacuum pump. One-click operation,power saving design.

3D Printing Soft Metal Sintering Furnace Features

- One-click to complete sintering, cooling, and pumping vacuum.

- Big furnace chamber.

- Powe consumption is 12KW per one process, one process takes 4 hours.

3D Printing Soft Metal Sintering Furnace Technical Parameters

| Furnace chamber size: | Ф180x350mm |

| Max temperature: | 1200℃ |

| Continuous work temp: | 0-1100℃ |

| Rated power: | 220V 50Hz 6kW |

| Controller: | ● 7-inch touch screen |

| ● Ti metal and Co-Cr metal annealing program | |

| ● Heating curve auto record | |

| ● Overheat alarm, sound-light alarm | |

| Temperature accuracy: | ±1℃ |

| Heating rate: | 20℃/min as the maximum |

| Vacuum level: | 99 KPa |

| Heating element: | Resistance wire |

| Furnace structure: | ● High strength carbon steel as the shell |

| ● Complete ceramic fiber as the chamber | |

| ● Double layer shell with the cooling fan | |

| ● Mitsubishi sealing fiber ring |

Note: The chamber and the max vacuum can be customized.

See our other Furnace:

Follow us on Facebook